Swannell Guitars - Original GROUND BUG - Ground lug pot washer

Please use the tabs below to read through the information about this product.

About

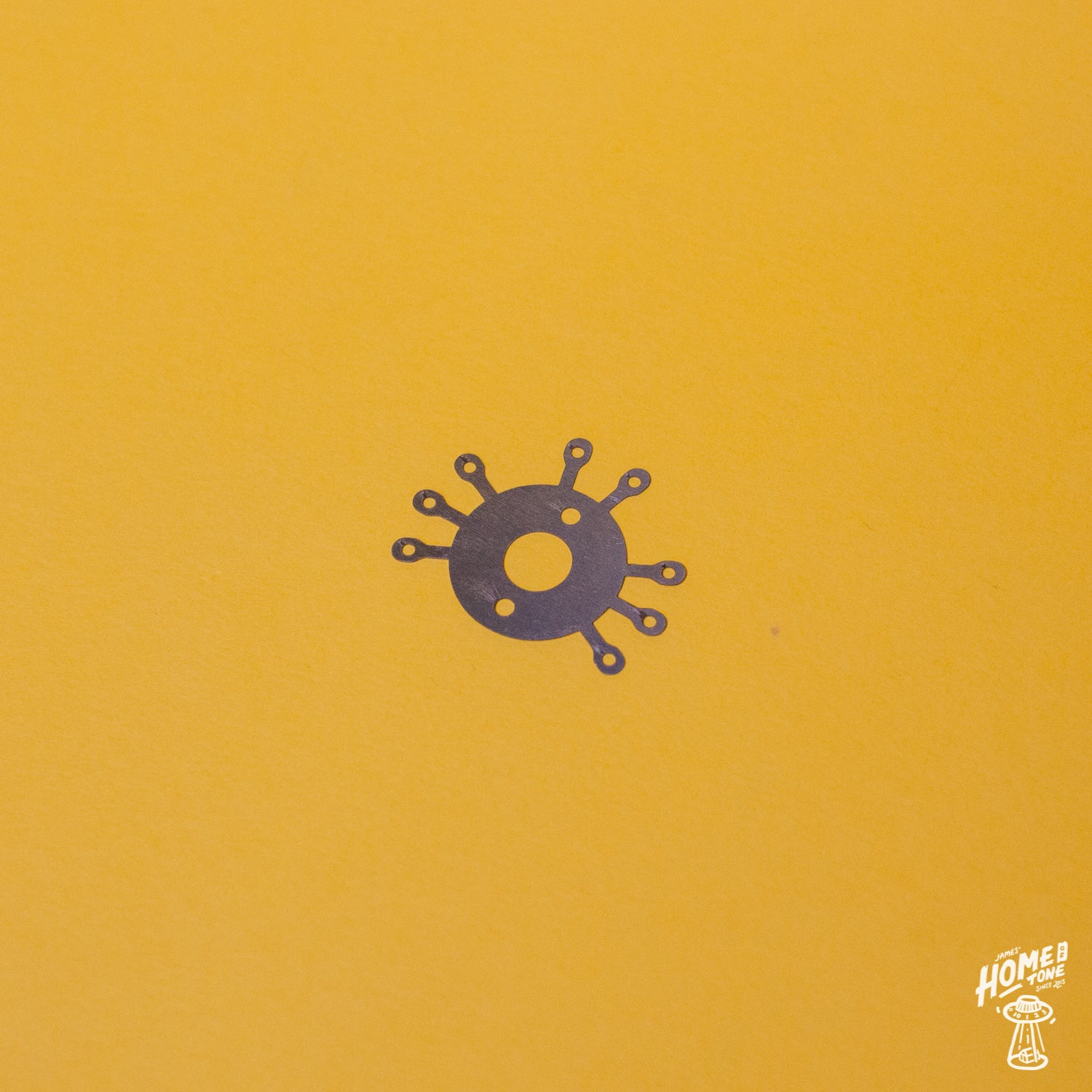

From the mind of UK based luthier, Jamie Swannell comes a really simple but genius helping hand for guitar wiring, the Ground Bug! This solder lug washer has some very handy uses indeed, from neatening up your wiring installs, to making ground connections easier and any future changes/mods/maintenance much easier too. So what is it?

This is a simple washer design that fits underneath your pots and has extended lugs so that you can easily solder ground wires to. This is very useful for those that perhaps really struggle with making, or consistently making ground wire solder connections to pot casings, drastically reducing the risk of damaging a pot from excessive heat for example. As with the Ground Bug installed, you simply solder your ground wires to any of the 8 lugs available.

You don't even need to solder the ground bug to the pot casing either, with it being used as a washer directly against the pot casing you will achieve ground continuity furthering it's ease of install. No more messy blobs of solder on the back of your pot casing, great for those that like neat looking installs. But neatness isn't just a visual thing, it also really helps for any maintenance in the future too, with each ground wire having it's own ground lug it makes replacing pickups, or even your pot a much easier process.

A brilliant, incredibly simple item that I think will really help installers of any experience/skill level. I'll certainly be using them and recommending them for as long as Jamie keeps making them! Proud to stock this great little wiring tool.

The Original Ground Bug

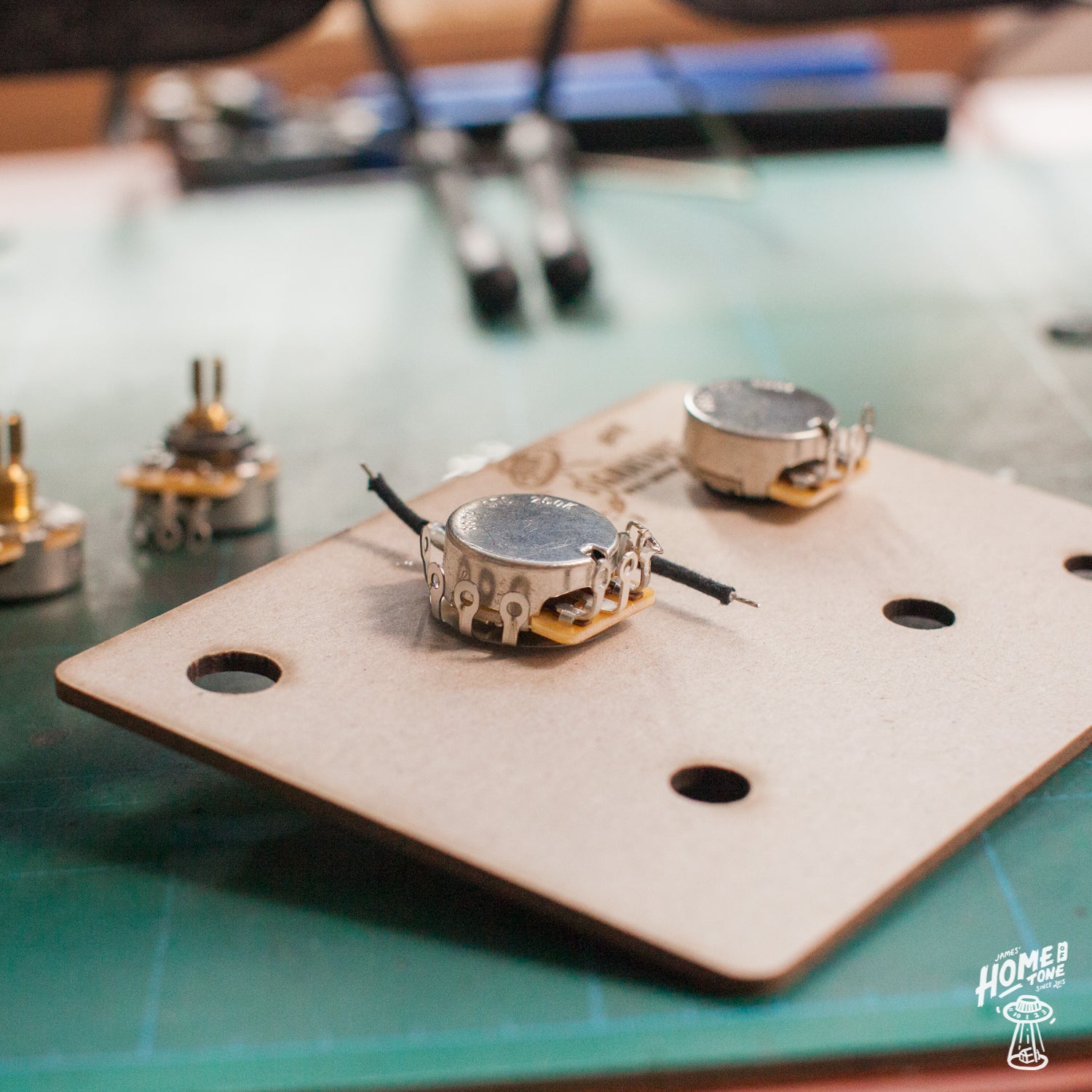

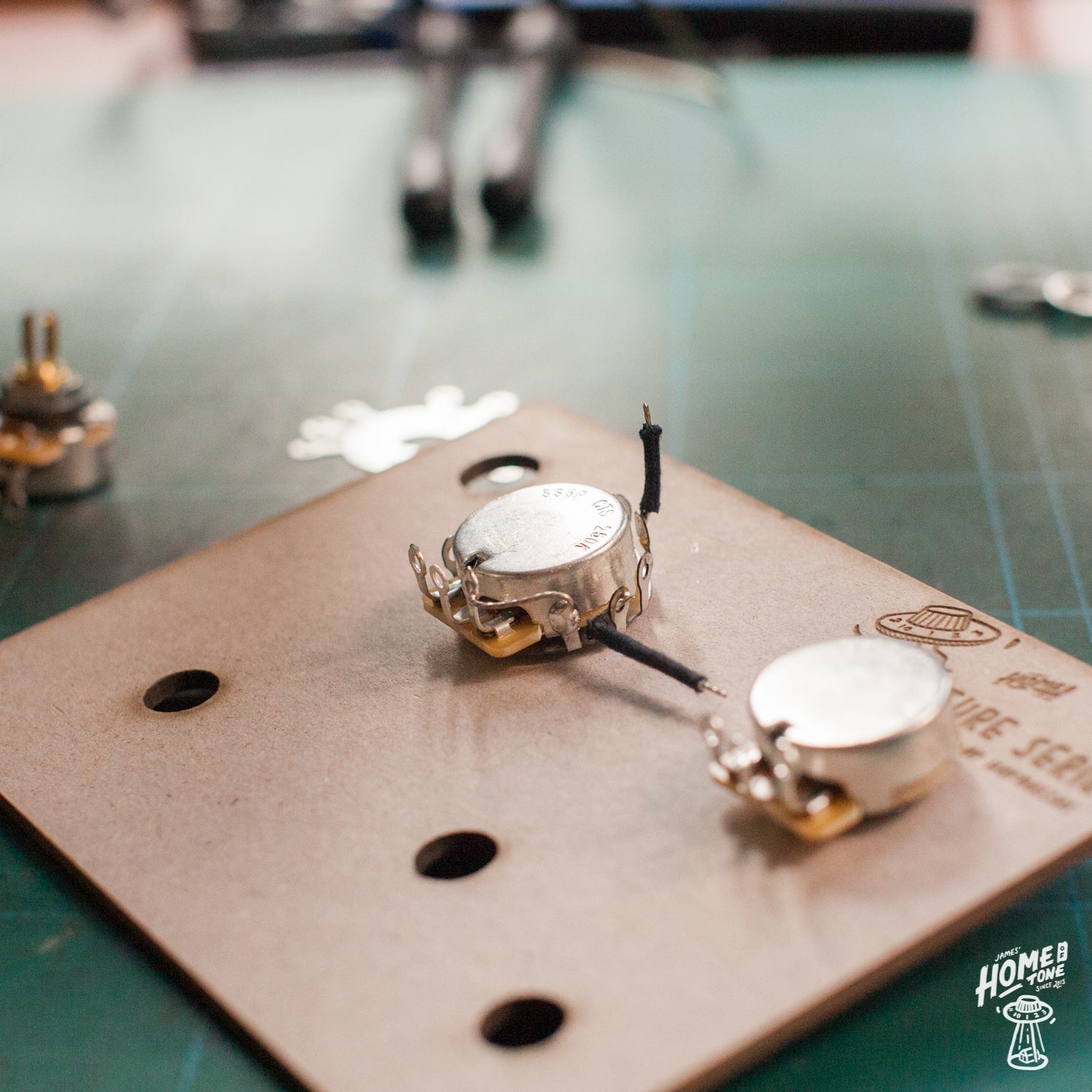

Where it all started! The Original Ground Bug features 8 total solder lugs, in three handy positions on the washer so when mounted up to the pot allows the installer to make use of whichever lugs best suit the access in the cavity or amount of wires needed to be soldered to ground. All whilst leaving ample space to clear the pots signal lugs too. You can leave it flat, or simply bend up the lugs to take up less space within the cavity to suit your requirements. The original ground bug can also be screwed/mounted directly to the body and has two small holes to help with this already machined.

It is made from the same material as the central lug on a CTS pot, so is super easy to solder onto!

Which pots will it fit?

The Original Ground Bug is designed to fit standard CTS pots, with it's 10mm mounting hole to suit their mounting thread diameter and can be installed simply as a washer between the pot and mounting surface. Or if you prefer, the ground bug can also be screwed/mounted directly to the body and has two small holes to help with this already machined.

I also think these will be incredibly useful for making pot casing ground connections on CTS push/pull pots too. The CTS push/pull features a rather large plastic casing on the back of the pot, meaning there is very little metal real estate for soldering any ground connections too. Even for a pro tech, these can be fiddly to work with and the ground bug will make a lot of installers lives easier when working with components like these for example.

Will it fit my guitar?

See the reference images on this listing to see how the footprint alters depending on whether you intend to install it flat, or with the lugs bent up. With the Ground Bug flat, it measures 44mm wide, at the widest point from end of lug to end of lug. It measures 35mm on the shortest point, edge of washer to end of lug. The central part (26.5mm) is ever so slightly wider than the footprint of a full size CTS pot, this is to allow you to be able to bend up the lugs should you wish, and leave clearance. Expect the footprint with the legs bent up to be around 27mm, a little wider if you angle the lugs of course.

I would personally recommend the Original Ground Bug for guitars with comfortable cavity space, or at least 3-5mm spare around the CTS pot casing within the cavity to allow access to the lugs with them bent up.

If you have a particularly tight control cavity, like a Telecaster for example, then I highly recommend ultilising the 'Daddy Long Legs' ground bug instead! That has been designed specifically for tighter cavities, so guitars like Telecasters, Les Paul Juniors or Fender Cabronita's for example which have a narrow routed control cavity, the Daddy Long Legs has been specifically designed for and therefore would recommend the DDL over this original Ground Bug for sure. But if your cavity has comfortable space around each pot, and suits all of the reference measurements I have detailed here, then I highly recommend the Original :)

Watch how they work

Here's a back to basics video I put together chatting about the ground bug and visually demonstrating how it can be used -

Ordering/shipping

Local pickup - If you are local and wish to collect any items or order in advance for collection on a specific day, then you can still place an order online and select local pickup at the checkout. Or drop me a message and I'll reserve the items ready for your visit.

For online ordering and dispatch - In stock, non made to order items are processed and dispatched 4 days a week; Monday, Tuesday, Wednesday & Friday.

For orders that are placed on a Monday, Tuesday, Wednesday & Friday I have an order cut off time of 14:00GMT (with Royal Mail shipping services only) to allow me chance to process, pack and dispatch your order same day.

For non dispatch days (Saturday, Sunday, & Thursday) there is no order cut-off time, and these will be processed, packed and shipped on the closest following dispatch day.

I will always endeavor to fulfill orders as quickly as I can and if you have specific requirements for a delivery date please do let me know and hopefully I can help.

If you have more queries regarding order placing, processing, fulfillment or general shipping then please see the FAQ page HERE

Please use the tabs below to read through the information about this product.

About

From the mind of UK based luthier, Jamie Swannell comes a really simple but genius helping hand for guitar wiring, the Ground Bug! This solder lug washer has some very handy uses indeed, from neatening up your wiring installs, to making ground connections easier and any future changes/mods/maintenance much easier too. So what is it?

This is a simple washer design that fits underneath your pots and has extended lugs so that you can easily solder ground wires to. This is very useful for those that perhaps really struggle with making, or consistently making ground wire solder connections to pot casings, drastically reducing the risk of damaging a pot from excessive heat for example. As with the Ground Bug installed, you simply solder your ground wires to any of the 8 lugs available.

You don't even need to solder the ground bug to the pot casing either, with it being used as a washer directly against the pot casing you will achieve ground continuity furthering it's ease of install. No more messy blobs of solder on the back of your pot casing, great for those that like neat looking installs. But neatness isn't just a visual thing, it also really helps for any maintenance in the future too, with each ground wire having it's own ground lug it makes replacing pickups, or even your pot a much easier process.

A brilliant, incredibly simple item that I think will really help installers of any experience/skill level. I'll certainly be using them and recommending them for as long as Jamie keeps making them! Proud to stock this great little wiring tool.

The Original Ground Bug

Where it all started! The Original Ground Bug features 8 total solder lugs, in three handy positions on the washer so when mounted up to the pot allows the installer to make use of whichever lugs best suit the access in the cavity or amount of wires needed to be soldered to ground. All whilst leaving ample space to clear the pots signal lugs too. You can leave it flat, or simply bend up the lugs to take up less space within the cavity to suit your requirements. The original ground bug can also be screwed/mounted directly to the body and has two small holes to help with this already machined.

It is made from the same material as the central lug on a CTS pot, so is super easy to solder onto!

Which pots will it fit?

The Original Ground Bug is designed to fit standard CTS pots, with it's 10mm mounting hole to suit their mounting thread diameter and can be installed simply as a washer between the pot and mounting surface. Or if you prefer, the ground bug can also be screwed/mounted directly to the body and has two small holes to help with this already machined.

I also think these will be incredibly useful for making pot casing ground connections on CTS push/pull pots too. The CTS push/pull features a rather large plastic casing on the back of the pot, meaning there is very little metal real estate for soldering any ground connections too. Even for a pro tech, these can be fiddly to work with and the ground bug will make a lot of installers lives easier when working with components like these for example.

Will it fit my guitar?

See the reference images on this listing to see how the footprint alters depending on whether you intend to install it flat, or with the lugs bent up. With the Ground Bug flat, it measures 44mm wide, at the widest point from end of lug to end of lug. It measures 35mm on the shortest point, edge of washer to end of lug. The central part (26.5mm) is ever so slightly wider than the footprint of a full size CTS pot, this is to allow you to be able to bend up the lugs should you wish, and leave clearance. Expect the footprint with the legs bent up to be around 27mm, a little wider if you angle the lugs of course.

I would personally recommend the Original Ground Bug for guitars with comfortable cavity space, or at least 3-5mm spare around the CTS pot casing within the cavity to allow access to the lugs with them bent up.

If you have a particularly tight control cavity, like a Telecaster for example, then I highly recommend ultilising the 'Daddy Long Legs' ground bug instead! That has been designed specifically for tighter cavities, so guitars like Telecasters, Les Paul Juniors or Fender Cabronita's for example which have a narrow routed control cavity, the Daddy Long Legs has been specifically designed for and therefore would recommend the DDL over this original Ground Bug for sure. But if your cavity has comfortable space around each pot, and suits all of the reference measurements I have detailed here, then I highly recommend the Original :)

Watch how they work

Here's a back to basics video I put together chatting about the ground bug and visually demonstrating how it can be used -

Ordering/shipping

Local pickup - If you are local and wish to collect any items or order in advance for collection on a specific day, then you can still place an order online and select local pickup at the checkout. Or drop me a message and I'll reserve the items ready for your visit.

For online ordering and dispatch - In stock, non made to order items are processed and dispatched 4 days a week; Monday, Tuesday, Wednesday & Friday.

For orders that are placed on a Monday, Tuesday, Wednesday & Friday I have an order cut off time of 14:00GMT (with Royal Mail shipping services only) to allow me chance to process, pack and dispatch your order same day.

For non dispatch days (Saturday, Sunday, & Thursday) there is no order cut-off time, and these will be processed, packed and shipped on the closest following dispatch day.

I will always endeavor to fulfill orders as quickly as I can and if you have specific requirements for a delivery date please do let me know and hopefully I can help.

If you have more queries regarding order placing, processing, fulfillment or general shipping then please see the FAQ page HERE